Scan Ding Talk contact

Scan Ding Talk contact

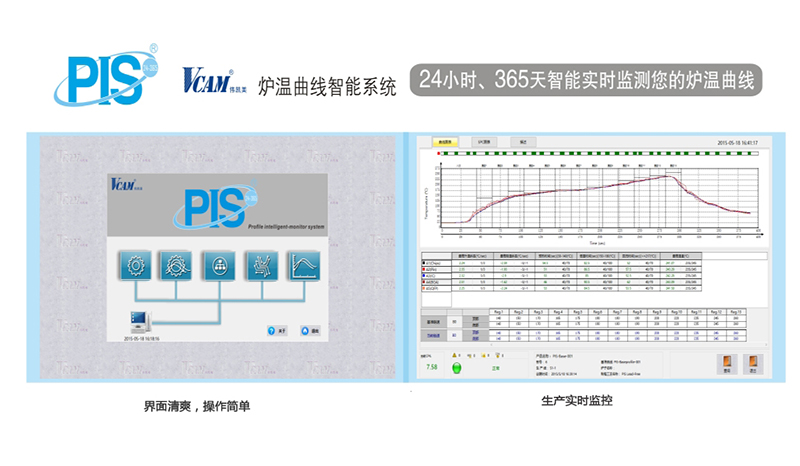

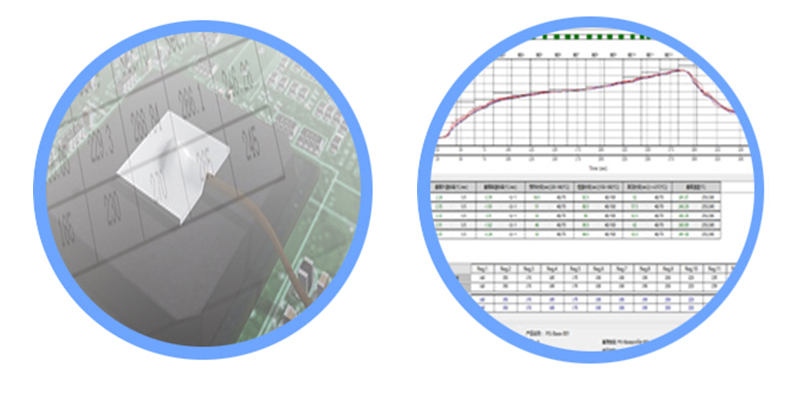

Classification query of production data: traceability of production data bar code - each PCB furnace pass curve will be saved automatically for future reference

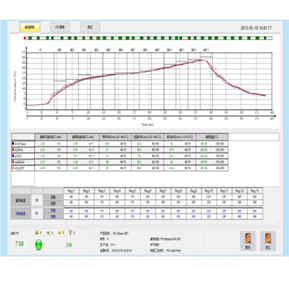

Production real-time monitoring interface: process temperature early warning, speed drift early warning - in the production process, each warning exceeding the process specification will be recorded automatically

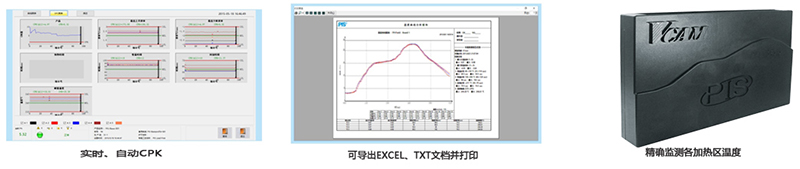

Hardware parameters of intelligent system of furnace temperature curve:

Temperature monitoring range: - 200 ℃ - 1200 ℃

Number of high channels supported: 48 channel data acquisition

Sampling resolution: 0.01 ℃

Sampling accuracy: ± 0.5 ℃

Communication mode: USB communication, network communication (strong expansibility)

Power supply mode: 12V DC

Link monitoring: real time measurement of chain speed of reflux furnace

Software parameters of intelligent system for furnace temperature curve:

Application platform: win7 32-bit, win7 64 bit, win8 32-bit,

Win8 64 bit, win10 32 bit, win10 64 bit

Language version: Simplified Chinese, traditional Chinese, English

Query method: time period, product name, barcode

Process alarm: furnace curve temperature warning, conveyor belt speed warning

Process warning, Cpk warning

View curve parameters: according to customer barcode rules, you can view every

Production information of a PCB

Email: admin@smtjhd.com

Tel: 0755-8461 5789

Address: 3 / F, building B, Zunlong hi tech park, No.7 Xieping Road, Ailian Industrial Zone, Wulian community, Longgang street, Longgang District, Shenzhen

|