Scan Ding Talk contact

Scan Ding Talk contact

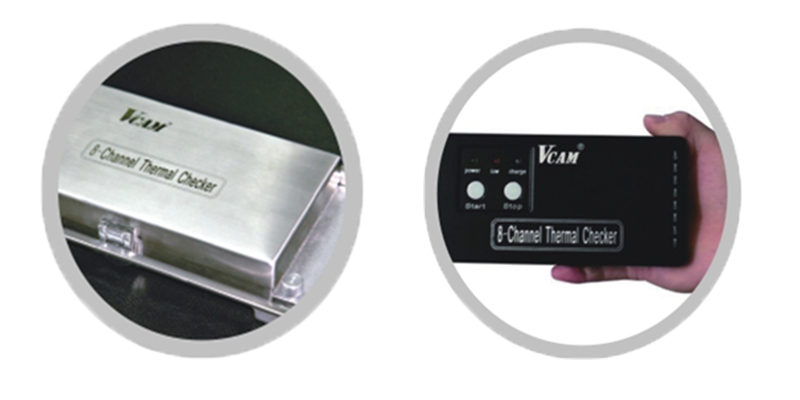

When we carry out the relevant test work, we are more concerned about the working effect of the furnace temperature tester. As a popular product representative in the field of furnace temperature tester manufacturers, furnace temperature tester is also widely used. What about the heat resistance of the needle? First of all, we should know that the results of using furnace temperature tester are more accurate. The process can be simplified to a number bar (PWI), so that you can understand the perfection of the temperature curve.

During the operation of the furnace temperature tester, the complex process setting is simplified by the automatic process, which makes the furnace temperature tester extremely simple, any operator can quickly obtain a good process. It is only necessary to define the process window automatically the furnace temperature tester specification of one hundred common solder paste suppliers, the color code signal will give an alarm to the operator in case of non conformance. By adopting the innovative technology, the tedious tasks that need to be performed when the traditional method is used to measure the temperature curve can be eliminated, the testing process of the furnace temperature tester can be accelerated. All areas of reflow soldering furnace the measurement of products by thermocouples are automatic. It can immediately determine the acceptability of process curve, reduce the number of required temperature curve tests, greatly reduce production downtime.

The manufacturer of furnace temperature tester analyzes that the simplified user interface can guide the operator to complete the whole temperature curve test process, greatly reducing the wrong temperature setting of reflow soldering furnace various defects affecting the output.

The main features of the furnace temperature tester are: 1. Superior heat resistance, light appearance (70% less than the previous model); 2. No adapter is needed to transfer data directly through USB line; 3. Memory can be cooled more effectively through the auxiliary cooling device; 4. The measurement accuracy is ± 1 ℃ (except for thermocouple error); 5. The new reflux furnace management software (TMR system) is installed Temperature prediction function statistical management system.

Email: admin@smtjhd.com

Tel: 0755-8461 5789

Address: 3 / F, building B, Zunlong hi tech park, No.7 Xieping Road, Ailian Industrial Zone, Wulian community, Longgang street, Longgang District, Shenzhen

|