Scan Ding Talk contact

Scan Ding Talk contact

The new round of scientific technological revolution industrial transformation are accelerating, the wave of automation intelligence in SMT industry is surging. Shenzhen jiehuiduo Technology Co., Ltd. is a domestic branch of weikaimei (Hong Kong) Co., Ltd. founded in 2003, has been committed to providing production auxiliary equipment, visual inspection furnace temperature measuring instruments, SMT matching for SMT (surface mounting) industry for 13 years since its establishment Consumables. Through years of market technology accumulation, the company is now a national high-tech professional company integrating independent R & D, production sales. With the product concept of "focusing on professional achievements, quality creating the future", the company provides a number of production auxiliary equipment, automation equipment intelligent software, independently produced SMT equipment accessories consumables for the electronic manufacturing industry.

As long as the idea is bold enough, the patent certificate will be soft

Jiehuiduo technology has a team with high education rich working experience. The main members of each team have 5-10 years of relevant working experience, including the R & D positions with bachelor degree above, the engineering service personnel with more than 5 years of actual working experience in SMT industry. Up to now, the company has obtained more than 10 national patent technologies. The company cultivates automation hardware software R & D, production technicians management talents, hoping to establish a wide long-term cooperative relationship with customers at home abroad; production auxiliary equipment spare parts consumables in SMT (surface mount) industry to many links in electronic production manufacturing process, it provides relevant automation equipment, visual inspection production intelligent management software for customers For professional, quality supporting services, so that customers have automatic, intelligent, intelligent electronic manufacturing products. The company has passed ISO9001:2008 international quality system certification 3C certification, constantly improve the production process of products to ensure the stable supply of products to meet customers' needs, fulfill the environmental protection responsibility of the enterprise.

Integrate intelligence automation to improve printing welding technology

At present, the products of jiehuiduo technology cover the SMT industry: printing, SMT welding. After years of continuous research development positioning, its VCAM brand helps customers meet the current demand for automation intelligence, helps industry 4.0.

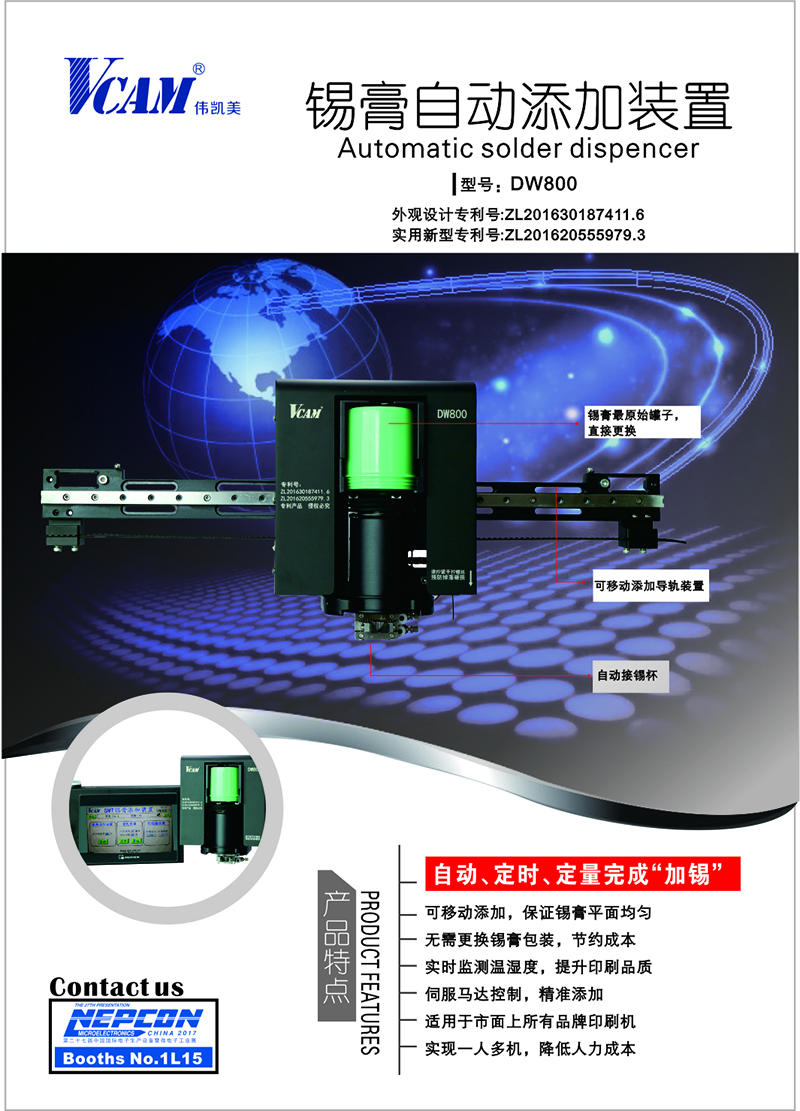

For SMT production process, printing plays an important role in the welding of the rear patch, so solder paste, steel mesh printing machine, as the three printing giants, solder paste addition, control cleaning are very important. At present, the solder paste automatic adding device introduced by jiehuiduo technology can only replace manual operation, but also realize one person with multiple machines reduce labor cost. It can realize real-time quantitative adding at any position within a certain range according to different needs, it can also monitor temperature humidity in real time, control servo motor, add accurately, improve printing quality. More importantly, it is suitable for all brand printing machines on the market, without changing the solder paste packaging, saving costs.

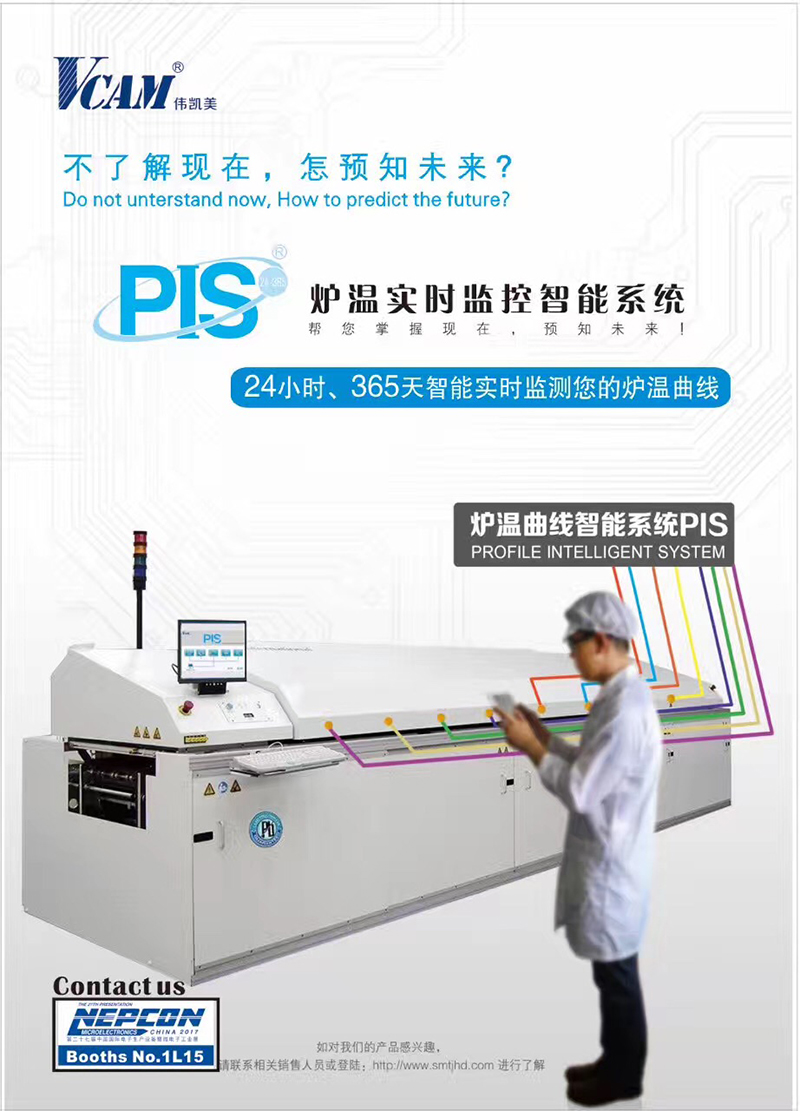

As the saying goes, "a good horse with a good saddle", how can a good hardware device lack a good combination of software it. The upgrading of automation is bound to be inseparable the development of intelligence, the future industrial road will be more more around the direction of intelligent automation. The pis24-365 furnace temperature real-time monitoring intelligent system of jiehui multi science technology can be applied to multiple windows system platforms to effectively identify the complex simple switching in Chinese English. It can classify the welding production data of the furnace (time period, product name, barcode, etc.) for query. The furnace temperature curve of each PCB passing through the furnace will be automatically saved for future reference. In addition, in the production process, the process temperature early warning type speed drift early warning, the production implementation monitoring interface will automatically record the warning beyond the process specification other welding process traceability, the stability reliability of the furnace real-time monitoring early warning.

The so-called "craftsmanship spirit" is fine production. Jiehuiduo technology provides one-stop service in printing welding. Considering that solder will leave residue affect the quality of paste production, the automatic nozzle cleaning machine produced by jiehuiduo technology adopts special mechanical automation design to crush pure water, mix it with high-pressure air, spray it to the top of SMT nozzle at high speed, spray it on the top of nozzle A high-pressure cleaning area is generated at the end, the solder paste impurities obstinate matters in the mouth are cleaned by means of high throwing vibration.

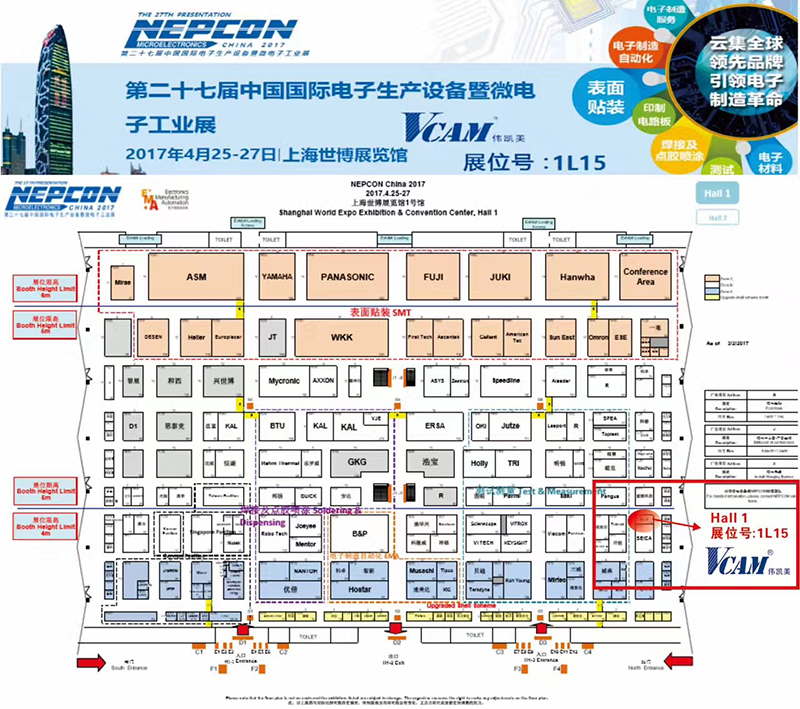

This automatic nozzle cleaning machine changes the previous one-to-one cleaning mode uses fixed cleaning heads to improve the alignment accuracy; at the same time, 24 cleaning heads work alternately, increasing the number of cleaning, greatly reducing the cleaning time; using automatic access doors to change the traditional alignment cleaning, to avoid alignment deviation, resulting in cleaning unclean; in addition, the control panel video panel are separated independently, real-time Monitor the internal conditions; increase the water level air pressure alarm system instead of manual detection, to avoid the efficiency drop equipment damage caused by negligence. With the transformation upgrading of China's manufacturing industry, automated intelligent smart factories have become the development direction of electronic manufacturing. In the future, the rapid, fine intelligent development of SMT industry will bring considerable changes to the manufacturing industry. Nepconchina China Electronic Exhibition, as a well-known influential exhibition in the electronic manufacturing industry, will start in Shanghai World Expo exhibition hall April 25 to 27. Jiehuiduo Technology Co., Ltd. will also bring the latest "i5 intelligent furnace temperature tester" to the exhibition site. Welcome to 1l15 booth for guidance.

Email: admin@smtjhd.com

Tel: 0755-8461 5789

Address: 3 / F, building B, Zunlong hi tech park, No.7 Xieping Road, Ailian Industrial Zone, Wulian community, Longgang street, Longgang District, Shenzhen

|